NLZ E / NLZ

QWarning: HE1 – If you continue to use a contra angle that was determined to be “NG” or “OIL” when the contra check function was performed, the contra heat prevention function will be activated and “HE1” will be displayed. - TS22467

A

- Action

-

Perform maintenance of the handpiece and then check the handpiece with <Contra-Check> function.

QWarning: HE0 – Overload or a risk of abnormal heating of the motor detected. <Motor overheat prevention function>* - TS22472

A

- Action

-

Avoid overloading the handpiece with heavy cutting, etc. and wait for the warning to disappear.

* If you continue using the product, the motor will stop and error code “E8” will be displayed.

QError Code: E0 – The motor shaft is locked. - TS22487

A

- Action

-

Check if the handpiece is connected properly.

QError Code: E1 – Over current in the circuit detected. - TS22495

A

- Action

-

Avoid overloading the handpiece with continuous heavy cutting, etc.

Press the foot pedal again to remove the error.

QError Code: E2 – Higher motor speed than rated value detected. - TS22498

A

- Action

-

Avoid overloading the handpiece with continuous heavy cutting, etc.

Press the foot pedal again to remove the error.

QError Code: E3 – The Motor drive IC (Integrated Circuit) chip on the board that controls the motor- has generated an error signal. - TS22501

A

- Action

-

Avoid overloading the handpiece with continuous heavy cutting, etc.

Press the foot pedal again to remove the error.

QError Code: E4 – High temperature of FET detected. - TS22504

A

- Action

-

Allow the unit to cool down and try again.

QError Code: E5 – Overvoltage input to the unit detected. - TS22507

A

- Action

-

Check proper connection of AC adaptor and AC power cord.

QError Code: E6 – Overvoltage of an LED light detected. - TS22513

A

- Action

-

Check the LED light connection.

QError Code: E7 – Detected a residual overvoltage when themotor was started. - TS22510

A

- Action

-

Wait for approx. 5 sec., then press the foot pedal again.

If the error does not disappear, check if the motor and motor cord are connected properly.

QError Code : E8(1) – A handpiece heat generation error was detected. - TS22700

A

- Action

-

Perform maintenance of the handpiece, and then check the handpiece by the Contra- Check.

QError Code: E8(2) – A heat generation error of the motor was detected. - TS22708

A

- Action

-

Leave the motor until it cools down.

QError Code: E9 – The motor does not start up. - TS22716

A

- Action

-

Check the motor connection.

QError Code: EC – Data cannot be saved to EPROM (Memory). - TS22713

A

- Action

-

Turn the power OFF and then ON again.

QError Code: ED – Signals from the sensor cannot be read. - TS22720

A

- Action

-

Check the connection of the motor to motor cord.

QError Code: EE – An Increased handpiece heat generation error was detected. - TS22719

A

- Action

-

Perform maintenance of the handpiece, and then check the handpiece by the Contra- Check.

QError Code: EF – Under-voltage input to the unit detected. - TS22725

A

- Action

-

Check proper connection of AC adaptor and AC power cord.

QThe LCD Display does not light. - TS22733

A

- Cause1

-

The power Switch is OFF.

- Action1

-

Turn ON the power.

- Cause2

-

The AC adapter or AC power cord is not connected correctly.

- Action2

-

Check the connection.

- Cause3

-

Internal Fuse is blown.

- Action3

-

Contact your Authorized NSK Dealer.

QThe motor does not run. - TS22736

A

- Cause1

-

The tubing, motor cord, AC adapter or AC power cord is not connected correctly.

- Action1

-

Check the connection.

- Cause2

-

The air pressure is not given, or not connected properly from the dental unit.

- Action2

-

Check the air pressure of the dental unit.

- Cause3

-

The LCD Display shows an error code.

- Action3

-

Refer to the error code. Refer to Operation Manual “7-1 Error Code”

QThe rotation speed of the motor does not rise. - TS22739

A

- Cause

-

The air pressure of the dental unit is lower than the “Upper limit of air pressure”

- Action

-

Set the Upper limit of the air pressure below the air pressure of the dental unit. Refer to Operation Manual “3-10 Changing the settings for various functions”

QBeeps continue to sound when turning ON the switch. - TS22744

A

- Cause

-

You are stepping on the foot pedal when turning on the power switch. (Safety function)

- Action

-

Do not step the foot pedal, and turn on the power switch.

QThe LED does not light. - TS22747

A

- Cause

-

End of life expectancy reached.

- Action

-

Contact your Authorized NSK Dealer.

QThe motor heats up abnormally during rotation. - TS22750

A

- Cause

-

Coolant air is not given, or not properly connected from the dental unit.

- Action

-

Check the air pressure on the side of the dental unit.

QWater leakage - TS24355

A

- Cause

-

The tubing, motor cord is not connected correctly.

- Action

-

Check the connection. If it is happening inside the control unit, contact your Authorized NSK Dealer.

QSettings when the power is turned ON are different from the previous ones when turning off the power. - TS22756

A

- Cause

-

The power is turned OFF using the main unit’s power switch.

- Action

-

Previous settings will not be retained when turning OFF the main unit’s power switch. Turn OFF using the control unit’s Power Key.

Varios Combi Pro2

QError indication - TS25130

QError code - TS25179

A

ERROR 0

- Description of error

-

System error

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 1

- Description of error

-

24 V voltage abnormality

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 2

- Description of error

-

12 V voltage abnormality

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 3

- Description of error

-

Pump current abnormality

- Check/Remedy

-

Check the connection of the irrigation pump. If the error still persists, contact your authorized NSK dealer.

ERROR 4

- Description of error

-

Air pressure abnormality

- Check/Remedy

-

Check the incoming air pressure. If the error still persists, contact your authorized NSK dealer.

ERROR 5

- Description of error

-

Heater voltage abnormality

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 6

- Description of error

-

Heater current abnormality

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 7

- Description of error

-

Heater temperature abnormality

- Check/Remedy

-

Check the water circuit, and then supply the control unit with water.

Cool down the control unit, and then operate it again.

If the error still persists, contact your authorized NSK dealer.

ERROR 8

- Description of error

-

Foot control communication abnormality

- Check/Remedy

-

Check the connection of the foot control. If the error still persists, contact your authorized NSK dealer.

ERROR 9

- Description of error

-

Ultrasonic handpiece abnormality

- Check/Remedy

-

Check the connection of the ultrasonic handpiece. If the error still persists, contact your authorized NSK dealer.

ERROR 10

- Description of error

-

Air proportional control valve current abnormality

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 12

- Description of error

-

Touch sensor communication abnormality

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 13

- Description of error

-

Ultrasonic unit self-check error

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

ERROR 14

- Description of error

-

Ultrasonic unit system error

- Check/Remedy

-

Turn off the control unit, and then turn it on again. If the error still persists, contact your authorized NSK dealer.

QThe screen does not display anything even when the power switch is turned on. - TS25185

A

- Cause1

-

The plug is improperly inserted to power source.

- Remedy1

-

Check to make sure that the plug is properly connected.

- Cause2

-

Malfunction of the power switch.

- Remedy2

-

Contact your authorized NSK dealer*.

- Cause3

-

The fuse has blown.

- Remedy3

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QA beep sounds. - TS25188

A

- Cause1

-

Power was turned on while the foot control was depressed.

- Remedy1

-

Release the foot control and turn the power switch on.

- Cause2

-

Abnormal heating of the control unit.

- Remedy2

-

Stop the operation and wait until the control unit cools down.

QTouch panel does not react well, or the touched key is not recognized correctly. - TS25191

A

- Cause1

-

Calibration is slightly misaligned due to static electricity, exogenous noise, etc.

- Remedy1

-

Turn the power switch off and then on.

- Cause2

-

The key was not touched at the center.

- Remedy2

-

Touch the center of the key.

- Cause3

-

Malfunction of the control unit.

- Remedy3

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QWater does not stop. The water level cannot be adjusted. - TS25194

A

- Cause1

-

Water volume adjustment dial has been damaged.

- Remedy1

-

Contact your authorized NSK dealer*.

- Cause2

-

Damage or wear of an O-ring.

- Remedy2

-

Replace the O-ring with a new one. Refer to Operation Manual "6.1.5 Chamber connector"

- Cause3

-

The water circuit has been clogged with foreign materials.

- Remedy3

-

Perform auto-cleaning. If the symptom is still not resolved, contact your authorized NSK dealer.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThere is no warm water. - TS25197

A

- Cause1

-

Malfunction of the control unit.

- Remedy1

-

Contact your authorized NSK dealer*.

- Cause2

-

Water temperature setting is "OFF".

- Remedy2

-

Set warm water to "ON". Refer to Operation Manual "7.3.2 Setting warm water"

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QWater is leaking from the bottle connector or irrigation bottle. - TS25200

A

- Cause1

-

Bottle lid is not tightened firmly.

- Remedy1

-

Firmly tighten the bottle lid.

- Cause2

-

Worn O-ring or gasket of the bottle lid.

- Remedy2

-

Replace the O-ring or gasket with a new one.

- Cause3

-

Irrigation bottle is not inserted all the way. (There is a gap between the irrigation bottle and the control unit.)

- Remedy3

-

Insert the irrigation bottle all the way.

Make sure that there is no gap between the irrigation bottle and the control unit.

QAfter the power is turned on, “CONNECT” or “PUSH FC” is displayed and the screen does not change. - TS25203

A

- Cause

-

The foot control could not be connected.

- Remedy

-

Perform the following steps.

1. When "PUSH FC" is displayed on the LCD, depress and hold the ON/OFF button of the foot control.

If the screen does not change after five minutes, touch

2. Replace the batteries with new ones.

3. Depress and hold the ON/OFF button of the foot control. If the screen does not change after five minutes, pair the control unit and the foot control again. Refer to Operation Manual "7.3.1 Pairing/unpairing foot control".

If the screen does not change after performing the steps 1 through 3, contact your authorized NSK dealer.

QThe product does not operate even when the ON/OFF button of the foot control is depressed. - TS25207

A

- Cause1

-

The foot control has not been connected.

- Remedy1

-

Perform the following steps.

1. Remove any obstructions between the control unit and the foot control (which may be blocking communication).

2. Turn off the power switch, and then turn it on again.

3. Replace the batteries of the foot control with new ones.

4. Pair the control unit and the foot control. Refer to Operation Manual "7.3.1 Pairing/unpairing foot control"

5. If the foot control cannot connect with the control unit after performing the steps 1 through 4, contact your authorized NSK dealer.*

- Cause2

-

Poor response of foot control buttons due to long periods of inactivity.

- Remedy2

-

Perform calibration of the foot control. Refer to Operation Manual "7.3.8 Foot control calibration"

- Cause3

-

Malfunction of the control unit or foot control.

- Remedy3

-

Perform the following steps.

1. Replace the batteries of the foot control with new ones.

2. Pair the control unit and the foot control. Refer to Operation Manual "7.3.1 Pairing/unpairing foot control"

3. Depress the ON/OFF button of the foot control to confirm that the product is operating.

If the product does not operate after performing the steps 1 through 3, repairs are required. Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe product operates although the ON/OFF button of the foot control is not depressed. - TS25210

A

- Cause

-

Malfunction of the control unit.

- Remedy

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe product does not stop although you lift your foot off the ON/OFF button. - TS25213

A

- Cause

-

Malfunction of the control unit.

- Remedy

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

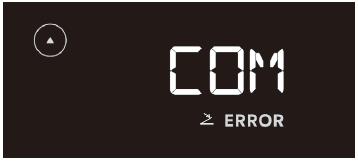

Q“COM ERROR” is shown on the display. - TS25216

A

- Cause

-

The foot control has not been connected.

- Remedy

-

Perform the following steps.

1. Touch  to cancel the error.

to cancel the error.

2. Remove any obstructions between the control unit and the foot control (which may be blocking communication).

3. Wait for the foot control to be automatically connected.

If it is not automatically connected, perform the following procedure:

1. Replace the batteries of the foot control with new ones.

2. Pair the control unit and the foot control. Refer to Operation Manual "7.3.1 Pairing/unpairing foot control"

3. Depress the ON/OFF button of the foot control to confirm that the product is operating.

If the error persists after performing the steps 1 through 3, repairs are required. Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

Q“BATTERY” is shown on the display. - TS25222

A

- Cause

-

The batteries of the foot control are running down.

- Remedy

-

Perform the following steps.

1. Depress the ON/OFF button of the foot control or touch  to cancel the "BATTERY" indication.

to cancel the "BATTERY" indication.

2. Replace the batteries of the foot control with new ones.

If the "BATTERY" indication does not disappear after performing the steps 1 through 2, repairs are required.

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QBeeps sound, and the ultrasonic mode display (P/E/G) and [icon A] flash alternately when the foot control button is depressed. (Ultrasonic mode) - TS25228

A

icon A:

- Cause

-

The sensor built inside the ultrasonic handpiece holder is soiled and mistakenly detects mounting of the ultrasonic handpiece.

- Remedy

-

Wipe off soil from the sensor built inside the ultrasonic handpiece holder.

QThere is no vibration or the vibration is poor. (Ultrasonic mode) - TS25235

A

- Cause1

-

The AC power cord plug is not connected to the wall socket, or electricity is not supplied to the wall socket.

- Remedy1

-

Check the connection.

- Cause2

-

The fuse has blown.

- Remedy2

-

Contact your authorized NSK dealer*.

- Cause3

-

The tip is not tightened firmly.

- Remedy3

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

- Cause4

-

The tip is worn.

- Remedy4

-

Replace the tip with a new one.

- Cause5

-

The threads of the ultrasonic handpiece and tip are not clean.

- Remedy5

-

Wipe them clean.

- Cause6

-

The threads of the ultrasonic handpiece are worn out as a result of long term use.

- Remedy6

-

Contact your authorized NSK dealer*.

- Cause7

-

Power has not been correctly adjusted for the tip.

- Remedy7

-

Adjust the power so that it does not exceed the set upper limit value mentioned in the supplied operation manual of the tip. Refer to Operataion Manual "1.2 Related manuals"

- Cause8

-

The foot control has not been connected.

- Remedy8

-

Pair the control unit and the foot control. Refer to Operation Manual "7.3.1 Pairing/unpairing foot control"

- Cause9

-

Failure of the vibration device in the ultrasonic handpiece.

- Remedy9

-

Contact your authorized NSK dealer*.

- Cause10

-

Failure of internal components of the foot control.

- Remedy10

-

Contact your authorized NSK dealer*.

- Cause11

-

The sensor built into the ultrasonic handpiece holder is dirty and mistakenly detects mounting of the ultrasonic handpiece.

- Remedy11

-

Wipe the sensor clean.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe tip is bent or broken. (Ultrasonic mode) - TS25238

A

- Cause

-

Power has not been correctly adjusted for the tip.

- Remedy

-

Adjust the power so that it does not exceed the set upper limit value mentioned in the supplied operation manual of the tip. Refer to Operation Manual "1.2 Related manuals"

QThe tip falls off. (Ultrasonic mode) - TS25241

A

- Cause

-

The tip is not tightened firmly.

- Remedy

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

QThe ultrasonic handpiece produces a loud noise. (Ultrasonic mode) - TS25244

A

- Cause1

-

Power has not been correctly adjusted for the tip.

- Remedy1

-

Adjust the power so that it does not exceed the set upper limit value mentioned in the supplied operation manual of the tip. Refer to Operation Manual "1.2 Related manuals"

- Cause2

-

The tip is not tightened firmly.

- Remedy2

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

- Cause3

-

Failure of the ultrasonic handpiece vibration device or control units internal components.

- Remedy3

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe ultrasonic handpiece is overheating. (Ultrasonic mode) - TS25256

A

- Cause1

-

Power has not been correctly adjusted for the tip.

- Remedy1

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

- Cause2

-

The tip is not tightened firmly.

- Remedy2

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

- Cause3

-

The threads of the ultrasonic handpiece and tip are not clean.

- Remedy3

-

Wipe them clean.

- Cause4

-

The threads of the ultrasonic handpiece are worn out as a result of long term use.

- Remedy4

-

Contact your authorized NSK dealer.

- Cause5

-

The irrigation level is insufficient or irrigation has stopped.

- Remedy5

-

Irrigate at an adequate volume.

- Cause6

-

Failure of the ultrasonic handpiece vibration device or control units internal components.

- Remedy6

-

Contact your authorized NSK dealer.

QNo irrigation supply and/or unstable irrigation supply. (Ultrasonic mode) - TS25262

A

- Cause1

-

The pump tube of the irrigation pump is twisted. (When using the bottle)

- Remedy1

-

Straighten the twisted irrigation tube.

- Cause2

-

It is time to replace the irrigation pump.

(When using the bottle)

- Remedy2

-

Replace the irrigation pump with a new one. Refer to Operation Manual "6.2 Replacing the pump"

QNo or poor water supply. (When using tap water) (Ultrasonic mode) - TS25265

A

- Cause1

-

Water is not supplied to the control unit.

- Remedy1

-

Check the water circuit so that water is supplied to the control unit. Supply water pressure: 0.1-0.3 MPa

- Cause2

-

The irrigation level has not been adjusted.

- Remedy2

-

Adjust the irrigation level by rotating the water volume adjustment knob. Refer to Operation Manual "When using tap water" in "3.13.1 Setting irrigation mode".

- Cause3

-

Water supply is sometimes unstable when the irrigation level is insufficient.

- Remedy3

-

This is not a malfunction. Adjust the irrigation level by rotating the water volume adjustment knob. Refer to Operation Manual "When using tap water" in "3.13.1 Setting irrigation mode".

- Cause4

-

The water filter is clogged with foreign substances.

- Remedy4

-

Replace the water filter with a new one. Refer to Operation Manual "6.3 Replacing the water filter"

QWater leaks. (Ultrasonic mode) - TS25268

A

- Cause

-

The water hose is not inserted into the water hose connector correctly.

- Remedy

-

Insert the water hose into the water hose connector fully and firmly. Refer to Operation Manual "3.3 Connecting water hose"

QUltrasonic handpiece LED does not light. (Ultrasonic mode) - TS25272

A

- Cause1

-

The O-ring of the connection part between the ultrasonic handpiece and handpiece cord is damaged or worn.

- Remedy1

-

Replace the O-ring with a new one. Refer to Operation Manual "6.1.1 Handpiece cord"

- Cause2

-

Failure in the control unit or handpiece cord.

- Remedy2

-

Contact your authorized NSK dealer*.

- Cause3

-

The glass rod of the ultrasonic handpiece is damaged as a result of a long term use.

- Remedy3

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

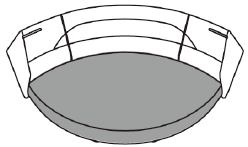

QAlarms sound, and [icon B] and [icon C] (tooth icon) flash alternately when the foot control ON/OFF button or operation mode/rinse button is depressed. (Powder mode) - TS25277

A

icon B:

icon C:

- Cause1

-

The sensor built inside the powder handpiece holder is dirty and mistakenly detects mounting of the powder handpiece.

- Remedy1

-

Wipe off soil from the sensor built inside the powder handpiece holder.

- Cause2

-

The chamber is not attached securely.

- Remedy2

-

Attach the chamber securely until you hear a click sound. Refer to Operation Manual "3.9 Attaching and removing chamber"

QNo notification sound, or the prophy mode [icon D] or perio mode [icon E] is not displayed even when the chamber is attached. (Powder mode) - TS25281

A

icon D:

icon E:

- Cause

-

Failure in the control unit (broken wire) Damage to the sensor built into the chamber.

- Remedy

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QAir and powder are not supplied, or air and powder are supplied but the pressure is not strong enough and cleaning power is also weak. (Powder mode) - TS25284

A

- Cause1

-

Nozzle is deformed or damaged.

- Remedy1

-

Replace the nozzle with a new one. Refer to Operation Manual "4.2.3 Operation" - "■ Attaching nozzle".

- Cause2

-

The inside of the nozzle tip is clogged with powder.

- Remedy2

-

Replace the nozzle tip with a new one. Refer to Operation Manual "4.2.3.2 Using in perio mode" - "■ Using nozzle tip".

- Cause3

-

The inside of the powder handpiece is clogged with powder.

- Remedy3

-

Perform the following steps.

1. Clean the nozzle base with the supplied cleaning wire (S).

2. Clean the nozzle end with the supplied cleaning file.

3. Clean the inside of the powder handpiece with the cleaning wire (L).

If powder and air do not flow after the cleaning described above, perform ultrasonic cleaning with warm water. Refer to Operation Manual "5.8 Ultrasonic cleaning (weekly)"

- Cause4

-

The inside of the chamber is clogged with powder.

- Remedy4

-

Remove powder from the chamber. Refer to Operation Manual "5.5.1 Removing powder"

- Cause5

-

Powder has partially solidified with water, etc., in the air passage.

- Remedy5

-

Remove powder from the air passage. Refer to Operation Manual "5.2.1 Ultrasonic"

- Cause6

-

Powder container has been left open exposing powder to the air.

- Remedy6

-

Dispose of the powder and use new powder

- Cause7

-

Water is mixed in supply air.

- Remedy7

-

Open the filter in the air supply circuit to drain the compressor, and check that water has not accumulated inside the air filter and compressor drain.

- Cause8

-

The element has been clogged.

- Remedy8

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QWater leaks from between the powder handpiece and handpiece hose. (Powder mode) - TS25290

A

- Cause

-

The O-ring is scratched.

- Remedy

-

Perform the following steps.

1. Replace the O-ring of the handpiece side connector of the handpiece hose.

2. Apply a drop of the supplied lubrication oil and rub it in with your finger. Refer to Operation Manual "6.1.2 Handpiece hose (Prophy-Hose2/Perio-Hose2)"

QAir leaks from between the chamber lid and the chamber. (Powder mode) - TS25293

A

- Cause

-

The gasket has been worn or damaged.

- Remedy

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe chamber lid cannot be tightened. (Powder mode) - TS25296

A

- Cause

-

Powder adheres to the threads of the chamber and/or the chamber lid.

- Remedy

-

Clean the threads of the chamber lid. Refer to Operation Manual "5.5.3 Cleaning chamber lid"

Varios Combi Pro

QBeeping sound (Ultrasonic Mode and Powder Mode) - TS18103

A

- Cause1

-

Power was turned on while the Foot Control was depressed.

- Remedy1

-

Release the Foot Control and turn the POWER switch to ON.

- Cause2

-

Abnormal heating of the Control Unit.

- Remedy2

-

Stop operation and leave until Control Unit cools.

QTouch panel does not react well or touched key is not recognized correctly. (Ultrasonic Mode and Powder Mode) - TS18113

A

- Cause1

-

Calibration is slightly misaligned due to static electricity, exogenous noise, etc.

- Remedy1

-

Turn the POWER switch to OFF and then to ON.

- Cause2

-

Key was not touched in the center.

- Remedy2

-

Touch the center of the key.

QWater does not stop / The water level cannot be adjusted (Ultrasonic Mode and Powder Mode) - TS18111

A

- Cause1

-

Damage or wear of the O-Ring.

- Remedy1

-

Follow the procedure in Operation Manual “10-1-5 Chamber Base Connector” to replace the O-Ring.

- Cause2

-

Foreign material has become clogged in the water line.

- Remedy2

-

Perform Auto-Cleaning. If the symptom is still not resolved, contact your Authorized NSK Dealer.

QAlarm sounds are heard, and the Ultrasonic Mode Display (P/E/G) and “ULTRASONIC” blink alternately when the Foot Control button D is depressed. (Ultrasonic Mode) - TS18072

A

- Cause

-

The sensor built in to the Handpiece Holder is dirty and mistakenly detects mounting of the Handpiece.

- Remedy

-

Wipe the sensor clean.

QNo/Poor vibration. (Ultrasonic Mode) - TS18099

A

- Cause1

-

The AC power cord plug is not connected to the wall socket or electricity is not supplied to the wall socket.

- Remedy1

-

Check the connection.

- Cause2

-

The Fuse is burned out.

- Remedy2

-

Refer to Operation Manual "10-5 Replacing the fuse" and replace the fuse.

- Cause3

-

The Tip is not tightened firmly.

- Remedy3

-

Rotate the Tip Wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the Tip Wrench as it may be worn out.

- Cause4

-

Worn Tip.

- Remedy4

-

Replace the Tip.

- Cause5

-

The screw parts of the Handpiece and Tip are not clean.

- Remedy5

-

Wipe them clean.

- Cause6

-

The screw parts of the Handpiece are worn out as a result of a long time of use.

- Remedy6

-

Contact your Authorized NSK Dealer.*

- Cause7

-

Power has not been correctly adjusted for the Tip.

- Remedy7

-

Adjust the power so it does not exceed the maximum power level mentioned in Tip-Power Guide or on the Tip case label.

- Cause8

-

The Foot Control is disconnected.

- Remedy8

-

Connect the Foot Control Cord lead correctly.

- Cause9

-

Failure of vibration device in the Handpiece.

- Remedy9

-

Contact your Authorized NSK Dealer.*

- Cause10

-

Failure of internal components of the Foot Control.

- Remedy10

-

Contact your Authorized NSK Dealer.*

- Cause11

-

The sensor built in to the Handpiece Holder is dirty and mistakenly detects mounting of the Handpiece.

- Remedy11

-

Wipe the sensor clean.

* Cannot be fixed at clinics, etc.

QThe Tip is bent or broken. (Ultrasonic Mode) - TS18095

A

- Cause

-

Power has not been properly adjusted for the Tip.

- Remedy

-

Adjust the power so it does not exceed the maximum power level mentioned in Tip-Power Guide or the Tip case label.

QThe Tip falls off. (Ultrasonic Mode) - TS18093

A

- Cause

-

The Tip is not tightened firmly.

- Remedy

-

Tighten the Tip until the Tip Wrench clicks.

QNoise from the Handpiece. (Ultrasonic Mode) - TS20996

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Remedy1

-

Adjust the power so it does not exceed the maximum power level mentioned in Tip-Power Guide or the Tip case label.

- Cause2

-

The Tip is not tightened firmly.

- Remedy2

-

Rotate the Tip Wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the Tip Wrench as it may be worn out.

- Cause3

-

Failure of vibration in the Handpiece or the Control Unit.

- Remedy3

-

Contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

QThe Handpiece is overheating. (Ultrasonic Mode) - TS21000

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Remedy1

-

Adjust the power so it does not exceed the maximum power level mentioned in Tip-Power Guide or the Tip case label.

- Cause2

-

The Tip is not tightened firmly.

- Remedy2

-

Rotate the Tip Wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the Tip Wrench as it may be worn out.

- Cause3

-

The screw parts of the Handpiece and Tip are not clean.

- Remedy3

-

Wipe them clean.

- Cause4

-

The screw parts of the Handpiece are worn out as a result of a long time of use.

- Remedy4

-

Contact your Authorized NSK Dealer.*

- Cause5

-

The Irrigation Volume is insufficient or irrigation has stopped.

- Remedy5

-

Irrigate at an adequate volume.

- Cause6

-

Vibration failure in the Handpiece or the Control Unit.

- Remedy6

-

Contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

QNo Irrigation supply and/or unstable Irrigation supply (when using the Bottle) (Ultrasonic Mode) - TS21005

A

- Cause1

-

The Irrigation Tube is twisted.

- Remedy1

-

Straighten the twisted Irrigation Tube.

- Cause2

-

Time to replace the Irrigation Pump.

- Remedy2

-

Replace with a new Irrigation Pump (Refer to Operation Manual "10-2 Changing the Irrigation Pump").

QNo/Poor water supply. (when using External Water) (Ultrasonic Mode) - TS21248

A

- Cause1

-

Water is not supplied to the Control Unit.

- Remedy1

-

Check the water circuit so that water is supplied to the Control Unit. Supply water pressure: 0.1 - 0.3MPa

- Cause2

-

The Irrigation Volume is set to “0.”

- Remedy2

-

Adjust to the adequate Irrigation Volume using the Irrigation Volume setting.

- Cause3

-

Water supply may be unstable when the Irrigation Volume is insufficient.

- Remedy3

-

This is not a malfunction. Increase the Irrigation Volume in the Irrigation Volume setting.

- Cause4

-

Water Filter is clogged with foreign substances.

- Remedy4

-

Replace the water filter with a new one.

QWater leakage. (Ultrasonic Mode) - TS21010

A

- Cause1

-

The Irrigation Tube is not connected correctly.

- Remedy1

-

Firmly insert the Irrigation Tube all the way into the Irrigation Connector.

- Cause2

-

O-Ring at the Handpiece Cord is worn or damaged.

- Remedy2

-

Replace with a new O-ring by following the procedures in Operation Manual "10-1-1 Handpiece Cord."

- Cause3

-

The water circuitry in the Control Unit is damaged.

- Remedy3

-

Contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

QHandpiece LED does not illuminate. (Ultrasonic Mode) - TS21013

A

- Cause1

-

The Handpiece is not connected to the Handpiece Cord correctly.

- Remedy1

-

Firmly insert the Handpiece all the way into the Handpiece Cord.

- Cause2

-

Failure in the Control Unit.

- Remedy2

-

Contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

QAlarms are heard, and “POWDER” and the tooth icon blink alternately when the Foot Control button D or B is depressed. (Powder Mode) - TS21016

A

- Cause1

-

The sensor built in to the Handpiece Holder is dirty and mistakenly detects mounting of the Handpiece.

- Remedy1

-

Wipe the sensor clean.

- Cause2

-

Chamber is not attached securely.

- Remedy2

-

Attach the Chamber securely until the confirmation sound is heard.

QConfirmation sound cannot be heard, or the icon that indicates Prophy Mode or Perio Mode is not displayed when the Chamber is attached. (Powder Mode) - TS21019

A

- Cause

-

Failure in the Control Unit (disconnection).

- Remedy

-

Contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

QAir and powder are not supplied. Or air and powder are supplied but the pressure is not strong enough and cleaning power is also weak. (Powder Mode) - TS21022

A

- Cause1

-

The inside of the Nozzle Tip is clogged with powder.

- Remedy1

-

Replace the Nozzle Tip.

- Cause2

-

The inside of the Handpiece is clogged with powder.

- Remedy2

-

Clean the Nozzle base with the supplied Cleaning wire (small) and Nozzle end with the cleaning file.

In addition, clean the inside of the Handpiece with the Cleaning wire (large). If powder and air do not flow after being cleaned as described above, perform Ultrasonic Cleaning with warm water. (Refer to Operation Manual “9-2-3 Ultrasonic Cleaning.”)

- Cause3

-

The inside of the Chamber is clogged with powder.

- Remedy3

-

Remove powder from inside the Chamber by following the procedures in Operation Manual "9-4 Cleaning the Chamber and Hose."

- Cause4

-

Powder has partially solidified with water, etc., in the air passage.

- Remedy4

-

Remove powder from inside the passage by following the procedures in Operation Manual "9-2-1 Auto- Cleaning."

- Cause5

-

Powder container has been left open exposing powder to the air.

- Remedy5

-

Dispose of the powder and use new powder.

- Cause6

-

Water is mixed in supply air.

- Remedy6

-

Open the filter in the air supply circuit to drain the compressor, and check that water has not accumulated inside the air filter and compressor drain.

- Cause7

-

The VCP Element is clogged.

- Remedy7

-

Contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

QWater leaks from between the Handpiece and Handpiece Hose. (Powder Mode) - TS21025

A

- Cause

-

The O-ring is chipped.

- Remedy

-

Replace the O-ring in the Handpiece joint section, apply the supplied turbine oil and rub it in with your finger. (Refer to Operation Manual "10-1-2 Handpiece Hose (for Prophy use and Perio use).")

QCannot remove the Chamber because the Lock Button cannot be pressed (Powder Mode) - TS21028

A

- Cause

-

The button is locked

- Remedy

-

Follow the procedure in “Releasing the Lock Button” in Operation Manual “9-4 Cleaning the Chamber and Hose” to release the Lock. If the symptom is not resolved, contact your Authorized NSK Dealer.*

* Cannot be fixed at clinics, etc.

Varios2 Ultrasonic Handpiece

QThere is no vibration or the vibration is poor. - TS25299

A

- Cause1

-

The threads of the ultrasonic handpiece are worn out as a result of a long time of use.

- Remedy1

-

Wipe them clean.

- Cause2

-

The threads of the ultrasonic handpiece are worn out as a result of long term use.

- Remedy2

-

Contact your authorized NSK dealer*.

- Cause3

-

Failure of the vibration device in the ultrasonic handpiece.

- Remedy3

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe ultrasonic handpiece produces a loud noise. - TS25302

A

- Cause1

-

Power has not been correctly adjusted for the tip.

- Remedy1

-

Adjust the power so that it does not exceed the set upper limit value mentioned in the supplied operation manual of the tip. Refer to Operation Manual "Related manuals"

- Cause2

-

The tip is not tightened firmly.

- Remedy2

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

- Cause3

-

Failure of the ultrasonic handpiece's vibration device or control unit's internal components.

- Remedy3

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QThe ultrasonic handpiece is overheating. - TS25303

A

- Cause1

-

Power has not been correctly adjusted for the tip.

- Remedy1

-

Adjust the power so that it does not exceed the set upper limit value mentioned in the supplied operation manual of the tip. Refer to Operation Manual "Related manuals"

- Cause2

-

The tip is not tightened firmly.

- Remedy2

-

Re-tighten the tip with the tip wrench by rotating the tip wrench until it makes a click sound and cannot rotate any further. If the problem still persists, replace the tip wrench as it may be worn out.

- Cause3

-

The threads of the ultrasonic handpiece are worn out as a result of a long time of use.

- Remedy3

-

Wipe them clean.

- Cause4

-

The threads of the ultrasonic handpiece are worn out as a result of long term use.

- Remedy4

-

Contact your authorized NSK dealer*.

- Cause5

-

Failure of the ultrasonic handpiece's vibration device or control unit's internal components.

- Remedy5

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

QDamage to the appearance or metal parts of the ultrasonic handpiece. - TS25312

A

- Cause

-

The ultrasonic handpiece has been dropped or deteriorated, or unspecified chemicals have been used.

- Remedy

-

Contact your authorized NSK dealer*.

* Cannot be fixed at dental clinics. Be sure to contact your authorized NSK dealer.

Water Bottle Kit

QIrrigation volume is low. - TS25315

A

- Cause1

-

Clogged filter due to deterioration over time.

- Remedy1

-

Air filter needs to be replaced.

Contact your authorized NSK dealer.

- Cause2

-

Bent or pinched water hose.

- Remedy2

-

Refer to Operation Manual "3.2 Connecting hose" and attach the water hose properly.

QWater leaking.(Bottle joint, bottom of the water bottle module, irrigation bottle, CLM bottle) - TS25318

A

- Cause1

-

Worn O-ring or gasket of the bottle lid.

- Remedy1

-

Replace the O-ring or gasket with a new one.

- Cause2

-

Damaged bottle or bottle lid.

- Remedy2

-

Replace the bottle or bottle lid with a new one.

QAir leaking. - TS25321

A

- Cause1

-

Damaged drive part inside the water bottle module.

- Remedy1

-

Contact your authorized NSK dealer.

- Cause2

-

Damaged air circuit part inside the water bottle module.

- Remedy2

-

Contact your authorized NSK dealer.

- Cause3

-

A supply air pressure outside of the specified value was used.

- Remedy3

-

Confirm the supply pressure and adjust to the specified pressure.

If air continues to leak after adjustment, contact your authorized NSK dealer.

QThe bottle cannot be removed. - TS25324

A

- Cause1

-

The O-ring is worn.

- Remedy1

-

Replace the O-ring.

- Cause2

-

Damage inside the water bottle module.

- Remedy2

-

Contact your authorized NSK dealer.

Varios 970

QNo/Poor vibration 1 - TS21180

A

- Probable Cause

-

The Front Panel does not light, even if the Power Switch is ON.

- Cause1

-

The Power Cord or the Jack is disconnected.

- Solution1

-

Correctly insert the Power Cord or the Jack.

- Cause2

-

The Fuse is burned out.

- Solution2

-

Contact dealer.*

* Repairs cannot be made by the customer.

QNo/Poor vibration 2 - TS21309

A

- Probable Cause

-

The Tip does not generate vibration, in spite of depressing the Foot Control.

- Cause1

-

The Tip is not tightened firmly.

- Solution1

-

Tighten the Tip until the Tip Wrench clicks.

- Cause2

-

Worn Tip.

- Solution2

-

Replace the Tip.

- Cause3

-

Power has not been correctly adjusted for the Tip.

- Solution3

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

- Cause4

-

The Foot Control is disconnected.

- Solution4

-

Connect the Foot Control correctly.

- Cause5

-

Failure of vibrator in the handpiece.

- Solution5

-

Contact dealer.*

- Cause6

-

Failure of internal components of the Foot Control.

- Solution6

-

Contact dealer.*

* Repairs cannot be made by the customer.

QThe Tip is bent or broken. - TS21214

A

- Cause

-

Power has not been properly adjusted for the Tip.

- Solution

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

QThe Tip is flying away. - TS21217

A

- Cause

-

The Tip is not tightened firmly.

- Solution

-

Tighten the Tip until the Tip Wrench clicks.

QNoise from the handpiece. - TS21220

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Solution1

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

- Cause2

-

The Tip is not tightened firmly.

- Solution2

-

Tighten the Tip until the Tip Wrench clicks.

- Cause3

-

Failure of vibration in the handpiece or the Control Unit.

- Solution3

-

Contact dealer.*

* Repairs cannot be made by the customer.

QThe handpiece is overheating. - TS21223

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Solution1

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

- Cause2

-

The Tip is not tightened firmly.

- Solution2

-

Tighten the Tip until the Tip Wrench clicks.

- Cause3

-

Failure of vibration in the handpiece or the Control Unit.

- Solution3

-

Contact dealer.*

* Repairs cannot be made by the customer.

QNo Irrigation supply and/or unstable Irrigation supply (Use of Bottle) - TS21226

A

- Probable Cause1

-

The Irrigation Pump is running.

- Cause1

-

The tube twisted.

- Solution1

-

Straighten the twisted Irrigation Tube.

- Probable Cause2

-

The Irrigation Pump is stopping.

- Cause2

-

Time to replace Irrigation Pump. (Approx. 500hours after used.)

- Solution2

-

Replace with new Irrigation Pump (Refer to Operation Manual "11. (3) Changing the Irrigation Pump").

QNo/Poor water. (Use of External Water)1 - TS21229

A

- Probable Cause

-

The water does not reach to the Control Unit.

- Solution

-

Check the water circuitry and supply to the Control Unit. Water pressure : 0.1-0.5MPa (1-5kgf/cm²)

QNo/Poor water. (Use of External Water)2 - TS21320

A

- Probable Cause

-

Check to see if water reaches the Control Unit.

- Cause1

-

The Water Adjustment Knob is closed.

- Solution1

-

Turn the Water Adjustment Knob and adjust to the appropriate volume.

- Cause2

-

Disconnected Irrigation supply at low volume range. (less than 10ml/min.)

- Solution2

-

No problem. Turn the Water Adjustment Knob and increase the Irrigation volume.

- Cause3

-

The Water Filter is clogged.

- Solution3

-

Replace with new Water Filter (Refer to Operation Manual "11. (5) Changing Water Filter (Option)" ).

QWater leakage. - TS21230

A

- Probable Cause1

-

Water is leaking from the joint between the Irrigation Tube and the Irrigation Connector.

- Cause1

-

The Irrigation Tube is not connected correctly.

- Solution1

-

Firmly insert the Irrigation Tube into the Irrigation Connector inmost.

- Probable Cause2

-

Water is leaking from the joint between the handpiece and the cord.

- Cause2

-

O-Ring at the handpiece cord is worn or damaged.

- Solution2

-

Replace with new O-Ring (Refer to Operation Manual "11 (2) Changing O-Ring •Handpiece Cord").

- Probable Cause3

-

Water is leaking from the Control Unit.

- Cause3

-

The water circuitry in the Control Unit is damaged.

- Solution3

-

Contact dealer.*

* Repairs cannot be made by the customer.

QHandpiece LED does not illuminate. (Varios 970 LUX) - TS21239

A

- Probable Cause1

-

Tip oscillates, but Handpiece LED turns on and off.

- Cause1

-

The handpiece is not connected into the Handpiece Cord correctly.

- Solution1

-

Firmly insert the handpiece into the Handpiece Cord inmost.

- Probable Cause2

-

Tip oscillates, but Handpiece LED does not turn on.

- Cause2

-

Disconnection in the Handpiece Cord, or failure in the Control Unit.

- Solution2

-

Contact dealer.*

* Repairs cannot be made by the customer.

QStart Beeping - TS21242

A

- Probable Cause1

-

Beeping while power on.

- Cause1

-

Depress Foot Control.

- Solution1

-

Release the Foot Control.

- Probable Cause2

-

Beeping while stopping vibration of Tips.

- Cause2

-

Abnormal heating of the Control Unit.

- Solution2

-

Stop the operation and leave until Control Unit becomes cool.

Varios 570

QNo/Poor vibration 1 - TS21255

A

- Probable Cause

-

Power Indicator does not light, even if the Power/Volume knob.

- Cause

-

The AC Adaptor or the DC Plug is disconnected.

- Solution

-

Correctly insert the AC Adaptor or the Jack.

QNo/Poor vibration 2 - TS21335

A

- Probable Cause

-

The Tip does not generate vibration, in spite of depressing the Foot Control.

- Cause1

-

The Tip is not tightened firmly.

- Solution1

-

Tighten the Tip until the Tip Wrench clicks.

- Cause2

-

Worn Tip.

- Solution2

-

Replace the Tip.

- Cause3

-

Power has not been correctly adjusted for the Tip.

- Solution3

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

- Cause4

-

The Foot Control is disconnected.

- Solution4

-

Connect the Foot Control correctly.

- Cause5

-

Failure of vibrator in the handpiece.

- Solution5

-

Contact dealer.

- Cause6

-

Failure of internal components of the Foot Control.

- Solution6

-

Contact dealer.

QThe Tip is bent or broken. - TS21260

A

- Cause

-

Power has not been properly adjusted for the Tip.

- Solution

-

Adjust the power level on the Power Guide or Tip case label. Do not exceed.

QThe Tip is flying away. - TS21263

A

- Cause

-

The Tip is not tightened firmly.

- Solution

-

Tighten the Tip until the Tip Wrench clicks.

QNoise from the handpiece. - TS21266

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Solution1

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

- Cause2

-

The Tip is not tightened firmly.

- Solution2

-

Tighten the Tip until the Tip Wrench clicks.

- Cause3

-

Failure of vibration in the handpiece or the Control Unit.

- Solution3

-

Contact dealer.

QThe handpiece is overheating. - TS21270

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Solution1

-

Adjust the power level on the power guide, as indicated on the Tip case label. Do not exceed the value shown.

- Cause2

-

The Tip is not tightened firmly.

- Solution2

-

Tighten the Tip until the Tip Wrench clicks.

- Cause3

-

Failure of vibration in the handpiece or the Control Unit.

- Solution3

-

Contact dealer.

QNo/Poor water 1 - TS21272

A

- Probable Cause

-

The water does not reach to the Control Unit.

- Solution

-

Check the water circuitry and supply to the Control Unit. Water pressure : 0.1-0.5MPa (1-5kgf/cm²)

QNo/Poor water 2 - TS21341

A

- Probable Cause

-

Check to see if water reaches the Control Unit.

- Cause1

-

The Water Volume Knob is closed.

- Solution1

-

Turn the Water Volume Knob and adjust to the appropriate Volume.

- Cause2

-

Disconnected Irrigation supply at low Volume range. (less than 10ml/min.)

- Solution2

-

No problem. Turn the Water Volume Knob and increase the Irrigation Volume.

- Cause3

-

The Water Filter is clogged.

- Solution3

-

Replace with new Water Filter (Refer to Operation Manual "11-3 Changing Water Filter (Option) ").

QWater leakge - TS21277

A

- Probable Cause1

-

Water is leaking from the joint between the handpiece and the cord.

- Cause1

-

O-Ring at the handpiece cord is worn or damaged.

- Solution1

-

Replace with new O-Ring (Refer to Operation Manual "11-2 Changing O-Ring Handpiece Cord")

- Probable Cause2

-

Water is leaking from the Control Unit.

- Cause2

-

The water circuitry in the Control Unit is damaged.

- Solution2

-

Contact dealer.

QHandpiece LED does not illuminate. (Varios2 Lux) - TS21280

A

- Probable Cause

-

Tip oscillates, but Handpiece LED turns on and off.

- Cause

-

The handpiece is not connected into the Handpiece Cord correctly.

- Solution

-

Firmly insert the handpiece into the Handpiece Cord inmost.

QLoss of the power output without operation. - TS21283

A

- Probable Cause

-

Power output is set 8 at G

- Cause

-

Protection Circuit is activated

- Solution

-

Power output will weaken automatically while continuous operation is over 10min at the setting of Maximum power at G mode. Releasing the foot from the Foot Control. Decrease the Power less than 5, once then increase the power again. (Refer to Operation Manual "7-5 Protection Circuit")

Varios 370

QNo/Poor vibration 1 - TS21368

A

- Probable Cause

-

The Power Indicator does not turn on,even if the power is ON

- Cause

-

The AC Adaptor or the DC Plug is disconnected

- Solution

-

Correctly insert the AC Adaptor or the DC Plug

QNo/Poor vibration 2 - TS21371

A

- Probable Cause

-

The Tip does not generate vibration, in spite of depressing the Foot Control

- Cause1

-

The Tip is not tightened firmly

- Solution1

-

Tighten the Tip until the Tip Wrench clicks

- Cause2

-

Worn Tip

- Solution2

-

Replace the Tip

- Cause3

-

Power has not been correctly adjusted for the Tip

- Solution3

-

Adjust the power level following the Power Guide or Tip case label. Do not exceed the power limit for the tip.

- Cause4

-

The Foot Control is disconnected

- Solution4

-

Connect the Foot Control correctly

- Cause5

-

Failure of vibrator in the handpiece

- Solution5

-

Contact dealer*

- Cause6

-

Failure of internal components of the Foot Control

- Solution6

-

Contact dealer*

* Repairs cannot be made by the customer.

QThe Tip is bent or broken - TS21375

A

- Cause

-

Power has not been properly adjusted for the Tip

- Solution

-

Adjust the power level following the Power Guide or Tip case label. Do not exceed the power limit for the tip.

QThe Tip falls off - TS21378

A

- Cause

-

The Tip is not tightened firmly

- Solution

-

Tighten the Tip until the Tip Wrench clicks

QNoise from the handpiece - TS21381

A

- Cause1

-

Power has not been properly adjusted for the Tip

- Solution1

-

Adjust the power level following the Power Guide or Tip case label. Do not exceed the power limit for the tip.

- Cause2

-

The Tip is not tightened firmly

- Solution2

-

Tighten the Tip until the Tip Wrench clicks

- Cause3

-

Failure of vibration in the handpiece or the Control Unit

- Solution3

-

Contact dealer*

* Repairs cannot be made by the customer.

QThe handpiece is overheating - TS21384

A

- Cause1

-

Power has not been properly adjusted for the Tip

- Solution1

-

Adjust the power level following the Power Guide or Tip case label. Do not exceed the power limit for the tip.

- Cause2

-

The Tip is not tightened firmly

- Solution2

-

Tighten the Tip until the Tip Wrench clicks

- Cause3

-

Failure of vibration in the handpiece or the Control Unit

- Solution3

-

Contact dealer*

* Repairs cannot be made by the customer.

QNo/Poor water 1 - TS21386

A

- Probable Cause

-

The water does not reach to the Control Unit

- Solution

-

Check the water circuitry and supply to the Control Unit. Water pressure : 0.1- 0.5MPa (1-5kgf/cm²)

QNo/Poor water 2 - TS21389

A

- Probable Cause

-

Check to see if water reaches the Control Unit

- Cause1

-

The Water Adjustment Knob is closed.

- Solution1

-

Turn the Water Volume Knob and adjust to the appropriate volume

- Cause2

-

Disconnected Irrigation supply at low volume range. (less than 10ml/min.)

- Solution2

-

No problem. Turn the Water Volume Knob and increase the Irrigation volume

- Cause3

-

The Water Filter is clogged

- Solution3

-

Replace with new Water Filter (Refer to Operation Manual "10-3 Changing Water Filter (Option)")

QWater leakage - TS21393

A

- Probable Cause

-

Water is leaking from the joint between the handpiece and the cord

- Cause

-

O-Ring at the handpiece cord is worn or damaged

- Solution

-

Replace with new O-Ring (Refer to Operation Manual "10-2 Changing O-Ring Handpiece Cord")

QAttachment of the Control Unit Holder is loose - TS21396

A

- Cause

-

The click of a holder was worn out

- Solution

-

Contact dealer*

* Repairs cannot be made by the customer.

QHandpiece LED does not illuminate. (Varios2 Lux) - TS21406

A

- Probable Cause

-

Tip oscillates, but Handpiece LED turns on and off

- Cause

-

The handpiece is not connected into the Handpiece Cord correctly

- Solution

-

Firmly insert the handpiece into the Handpiece Cord

QLoss of the power output without operation - TS21399

A

- Probable Cause

-

Power output is set 8 at G

- Cause

-

Protection Circuit is activated

- Solution

-

Power output will weaken automatically while continuous operation is over 10min at the setting of Maximum power at G mode. Releasing the foot from the Foot Control. Decrease the Power less than 5, once then increase the power again. (Refer to Operation Manual "6-5 Protection Circuit")

Varios 170

QNo/Poor vibration. - TS21409

A

- Item to Check

-

The Tip does not generate vibration, in spite of depressing the Foot Control.

- Cause1

-

The Tip is not tightened firmly.

- Solution1

-

Tighten the Tip until the Tip Wrench clicks.

- Cause2

-

Worn Tip.

- Solution2

-

Replace the Tip.

- Cause3

-

Power has not been correctly adjusted for the Tip.

- Solution3

-

Adjust the power level on the Power Guide. Do not exceed the maximum indicated on the tip label.

- Cause4

-

Failure of vibrator in the handpiece.

- Solution4

-

Contact dealer.*

* Repairs cannot be made by the customer.

QThe Tip is bent or broken. - TS21414

A

- Cause

-

Power has not been properly adjusted for the Tip.

- Solution

-

Adjust the power level on the Power Guide. Do not exceed the maximum indicated on the tip label.

QThe Tip is flying away. - TS21417

A

- Cause

-

The Tip is not tightened firmly.

- Solution

-

Tighten the Tip until the Tip Wrench clicks.

QNoise from the handpiece. - TS21420

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Solution1

-

Adjust the power level on the Power Guide. Do not exceed the maximum indicated on the tip label.

- Cause2

-

The Tip is not tightened firmly.

- Solution2

-

Tighten the Tip until the Tip Wrench clicks.

- Cause3

-

Failure of vibration in the handpiece or the Module.

- Solution3

-

Contact dealer.*

* Repairs cannot be made by the customer.

QThe handpiece is overheating. - TS21423

A

- Cause1

-

Power has not been properly adjusted for the Tip.

- Solution1

-

Adjust the power level on the Power Guide. Do not exceed the maximum indicated on the tip label.

- Cause2

-

The Tip is not tightened firmly.

- Solution2

-

Tighten the Tip until the Tip Wrench clicks.

- Cause3

-

Failure of vibration in the handpiece or the Module.

- Solution3

-

Contact dealer.*

* Repairs cannot be made by the customer.

QNo/Weak water 1 - TS21425

A

- Item to Check

-

The water does not reach to the handpiece.

- Solution

-

Check the water circuitry and supply to the Unit Chair.

QNo/Weak water 2 - TS21428

A

- Item to Check

-

Remove the handpiece from the handpiece cord. Water does not come out or only a limited amount.

- Cause1

-

The water adjustment dial is closed.

- Solution1

-

Turn the water adjustment dial and set it to an appropriate water level.

- Cause2

-

The water filter is clogged.

- Solution2

-

Contact dealer.*

* Repairs cannot be made by the customer.

QNo/Weak water 3 - TS21431

A

- Item to Check

-

No/Weak water from the handpiece.

- Cause

-

There may be exogenous material in the hole.

- Solution

-

Air it with the appliances such as syringes from the rear of the handpiece.

If it is still unsolved, contact dealer.

QWater leakage. - TS21434

A

- Item to Check

-

Water is leaking from the joint between the handpiece and the cord.

- Cause

-

O-Ring at the handpiece cord is worn or damaged.

- Solution

-

Apply air from an appliance such as a 3in1 syringe to the rear of the handpiece.

If it is still unsolved, contact dealer.

QHandpiece LED does not illuminate. (Varios 170 LUX) - TS21437

A

- Item to Check1

-

Tip oscillates, but Handpiece LED turns on and off.

- Cause1

-

The handpiece is not connected into the Handpiece Cord correctly.

- Solution1

-

Firmly insert the handpiece into the Handpiece Cord.

- Item to Check2

-

Tip oscillates, but Handpiece LED does not turn on.

- Cause2

-

Disconnection in the Handpiece Cord, or failure in Module.

- Solution2

-

Contact dealer.*

* Repairs cannot be made by the customer.

VarioSurg 4

QError Code: E0 – System error - TS23149

A

- Cause of error

-

Self-check error.

- Action

-

Request repair.

QError Code: E1 – Oscillator system error - TS23155

A

- Cause of error1

-

Tip is overloaded.

- Action1

-

Be careful not to overload the tip.

In the event of a situation where the tip is stuck in situe, step on the main pedal on the foot control and slowly pull out the tip while oscillating it (do not force it out).

- Cause of error2

-

Tip not mounted, tip not tightened enough.

- Action2

-

Install the tip and tighten it with the tip replacement wrench until it "clicks" and idles.

- Cause of error3

-

Handpiece cord is not securely connected. Disconnection in the handpiece cord.

- Action3

-

Check the handpiece cord connection. If this does not resolve it, contact an authorized NSK dealer.

QError Code: E2 – Power supply error - TS23158

A

- Cause of error

-

Insufficient contact of the power cord.

Failure of the power supply circuit.

- Action

-

Securely re-connect the power cord.

If the error cannot be eliminated, request repair.

QError Code: E4 – Control unit interior overheating error - TS23161

A

- Cause of error

-

Overheating by extended use under heavy load.

Use immediately after the control unit is placed at high temperature (such as inside a car under the blazing sun or in a locker exposed to direct sunlight).

- Action

-

Allow it to cool down before use.

To allow heat to be sufficiently radiated, the periphery of the control unit should be well ventilated wherever possible.

If the error cannot be eliminated, request repair.

QError Code: E7 – Irrigation pump error - TS23164

A

- Cause of error

-

Irrigation tube caught on pump roller.

Irrigation pump failure.

- Action

-

Check the irrigation tube.

If the error cannot be eliminated, request repair.

QError Code: E8 – Connection error in the control unit - TS23167

A

- Cause of error

-

Failure of Bluetooth communication circuit (LED handpiece system) inside the control unit.

- Action

-

Request repair.

QError Code: E9 – Wireless foot control error - TS23170

A

- Cause of error

-

Failure of sensor in wireless foot control.

Detection of disconnection of Bluetooth communication during ultrasonic vibration.

- Action

-

Request repair.

QError Code: E10 – Handpiece connection error - TS23173

A

- Cause of error

-

Handpiece or tip not connected.

- Action

-

Check that the handpiece cord is securely connected or that the tip is securely connected using a tip wrench.

If not resolved, contact an authorized NSK dealer.

QError Code: E11 – Operation panel error - TS23176

A

- Cause of error

-

Abnormal control panel screen

- Action

-

Request repair.

QError Code: E12 – Connection error in the control unit - TS23179

A

- Cause of error

-

Failure of the Bluetooth communication circuit (link system with Surgic Pro2) inside the control unit.

- Action

-

Request repair.

QError Code: E13 – Wired foot control error - TS23182

A

- Cause of error

-

Failure of wired foot control.

- Action

-

Make sure the connector of the wired foot control is securely connected. If not resolved, contact an authorized NSK dealer.

QScreen is blank. - TS23185

A

- Cause of problem1

-

Plug improperly inserted to power source

- Action1

-

Check to make sure the plug is in.

- Cause of problem2

-

Malfunction of power switch

- Action2

-

Request repair.

QThe power level and ” – – – ” are alternately displayed on LCD. - TS23190

A

- Cause of problem1

-

Power turned on while pressing the foot control

- Action1

-

Remove foot from foot control.

- Cause of problem2

-

Foot control malfunction

- Action2

-

If the problem is solved by removing the batteries, it is a foot control malfunction. If not, it is a control unit malfunction. Please contact an authorized NSK dealer.

- Cause of problem3

-

Control unit malfunction

- Action3

-

If the problem is solved by removing the batteries, it is a foot control malfunction. If not, it is a control unit malfunction. Please contact an authorized NSK dealer.

QAfter the power is ON, “CONNECT” or “PUSH FC” is displayed and the screen is not switched. - TS23193

A

- Cause of problem

-

Wireless foot control is not connected.

Keep pressing the main pedal of the wireless foot control while “PUSH FC” is displayed on the LCD.

If the screen does not change after 5 minutes, press the button below.

The normal screen is displayed.

Replace the wireless foot control batteries to check if it can be connected.

=> Refer to Operation Manual “3.2 Installing batteries (Only for wireless foot control)”.

If it cannot be connected after replacing the batteries, pairing the control unit and wireless foot control.

=> Refer to Operation Manual “7.2 Pairing with wireless foot control”.

If this does not resolve the issue, please contact an authorized NSK dealer.

QWill not vibrate even if the Wireless foot control is pressed. - TS23202

A

- Cause of problem

-

Wireless foot control is not connected.

- Action

-

Perform the following after confirming that nothing is blocking the signal between the wireless foot control and control unit.

・Turn the main power switch OFF, and ON again to connect to the control unit.

・Replace the wireless foot control batteries with new ones.

=>Refer to Operation Manual “3.2 Installing batteries (Only for wireless foot control)”.

・Perform pairing the control unit and wireless foot control.

=>Refer to Operation Manual “7.2 Pairing with wireless foot control”.

If this does not resolve the issue, please contact an authorized NSK dealer.

Surgic Pro2

QError code:E0 – System error - TS18135

A

- Cause of Error

-

Self-check error.

- Action

-

Request repair.

QError code: E1 – Motor voltage / current detection error - TS18034

A

- Cause of Error

-

Extended use under heavy load.

Short circuit in the motor.

Motor cord (power line) failure.

- Action

-

Electrical contact may be insufficient.

Securely re-connect the motor cord.

If the error cannot be eliminated, request repair.

QError code: E2 – Power supply error - TS18141

A

- Cause of error

-

Insufficient contact of the power cord.

Failure of the power supply circuit.

- Action

-

Securely re-connect the power cord.

If the error cannot be eliminated, request repair.

QError code: E3 – Motor sensor error - TS18139

A

- Cause of error

-

Motor sensor failure.

Unplugged motor cord.

Motor cord (signal line) failure.

Ingress of water into the motor.

- Action

-

Electrical contact may be insufficient.

Securely re-connect the motor cord.

If the error cannot be eliminated, request repair.

(Make sure to attach a protection plug when cleaning in a washer-disinfector.)

QError code: E4 – Control unit interior overheating error - TS18154

A

- Cause of error

-

Overheating by extended use under heavy load.

Use immediately after the control unit is placed at high temperature (such as inside a car under the blazing sun or in a locker exposed to direct sunlight).

- Action

-

Allow it to cool down before use.

To allow heat to be sufficiently radiated, the periphery of the control unit should be well-ventilated wherever possible.

If the error cannot be eliminated, request repair.

QError code: E5 – Breaking error - TS18160

A

- Cause of error

-

Abnormal voltage generated in the start / stop switch circuit.

Failure in the start / stop switch circuit.

- Action

-

When rotation and stop are repeated in a short period of time, a circuit to suppress the sudden acceleration at the start of rotation may be activated. Wait for a few seconds before use.

If the error cannot be eliminated, request repair.

QError code: E6 – Motor rotation failure error - TS18133

A

- Cause of error

-

Bur or drill attachment failure.

Handpiece failure.

Motor failure.

- Action

-

The chuck may still be open, or not sufficiently closed. Securely close the chuck.

If the error cannot be eliminated, request repair.

QError code: E7 – Irrigation pump error - TS18165

A

- Cause of error

-

Incorrectly fitted irrigation tubing caught in the pump roller.

Irrigation pump failure.

- Action

-